Snowed In 1500 KVA Dry Type Transformer

What happens when you ship a 1500 kva dry type power transformer in the winter, up North, without properly tarping it? It gets 86’d. Send it back. We don’t want it. Besides the snow and ice, there will be dirt, small debris, and very sad faces. Pictures do not do justice to the amount of snow and dirt on the windings. It can be a chore securing a dry type power transformer for shipment, what we call “Bagging it,” but it has to be done. Hidden openings in the tarping on the bottom are usually the culprit. Driving in the rain can be even worse if there is any opening in the tarp. When this happens there’s a lot of discussion about cleaning the transformer and drying it; Procedures; Warranties; Who’s going to pay for the shipping; and, of course, who is going to pay for a new transformer because the customer sure does not want to accept a brand new but wet and dirty 1500 kva, 13,200 volt to 480/277 volt transformer. It’s deficient. That’s all they know. Any suggestion the warranty protects the customer’s interest is met with open anger. A warranty is only for 2 ½ to 5% of the expected life of the transformer. And the cost of taking out an old unit and installing a new transformer can be horribly expensive. A large dry type power transformer is sometimes buried deep within a building’s structure. Sometimes the building has expanded around the transformer substation. We have seen many projects where the cost of the replacement transformer was less than the cost of the installation. Think of the cost of not properly securing the transformer from rain, snow and road dirt as being $1,500.00 per minute of the time it would have taken to do it right. Fortunately this does not happen very often.

An Electrical Contractor called MIDWEST with an emergency. A customer lost a 1500 kva dry type power transformer. The voltage was 13,200 to 480. Two of the fuses in the primary load break switch had blown. They checked things out and couldn’t find anything wrong, but wanted MIDWEST to test the transformer anyway. Meanwhile they checked out the secondary switchgear and a 480 volt to 208 volt dry type transformer in the same room as the switchgear. They found no smell and no smoke, so they figured they might get lucky, although we both knew that was not very probably. When 15kv, 100 amp fuses blow, a lot of energy went somewhere. The 1500 kva dry type transformer was a typical indoor unit substation type, with LAs, cooling fans and a fan control package. When we got there, the electrical contractor already had the panels off the switchgear and transformer, and everything properly grounded. They offered to help haul up the test equipment, which is always nice, but we said to hold off for a minute. It took 15 seconds to get our flashlight and then it took another 15 seconds to inspect the transformer and tell them the transformer had failed and they needed to get a replacement transformer or a rental transformer. Their skepticism was obvious, and for good reason. But we showed them the debris that had blown out the bottom of the center high voltage winding. Then had them look down through ventilation ports of the blown high voltage winding so they could see the blown out turns within the high voltage winding. They understood immediately. We ran a quick turns ratio test to document the failure. A case of seeing is believing.

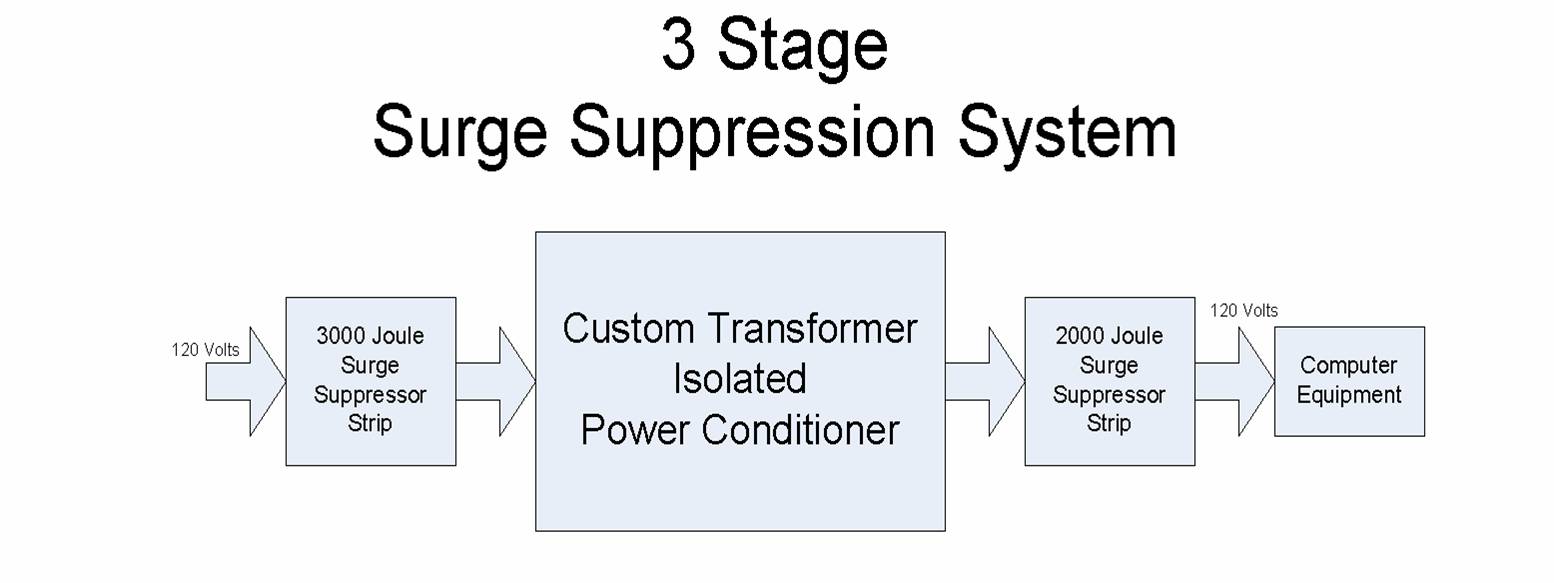

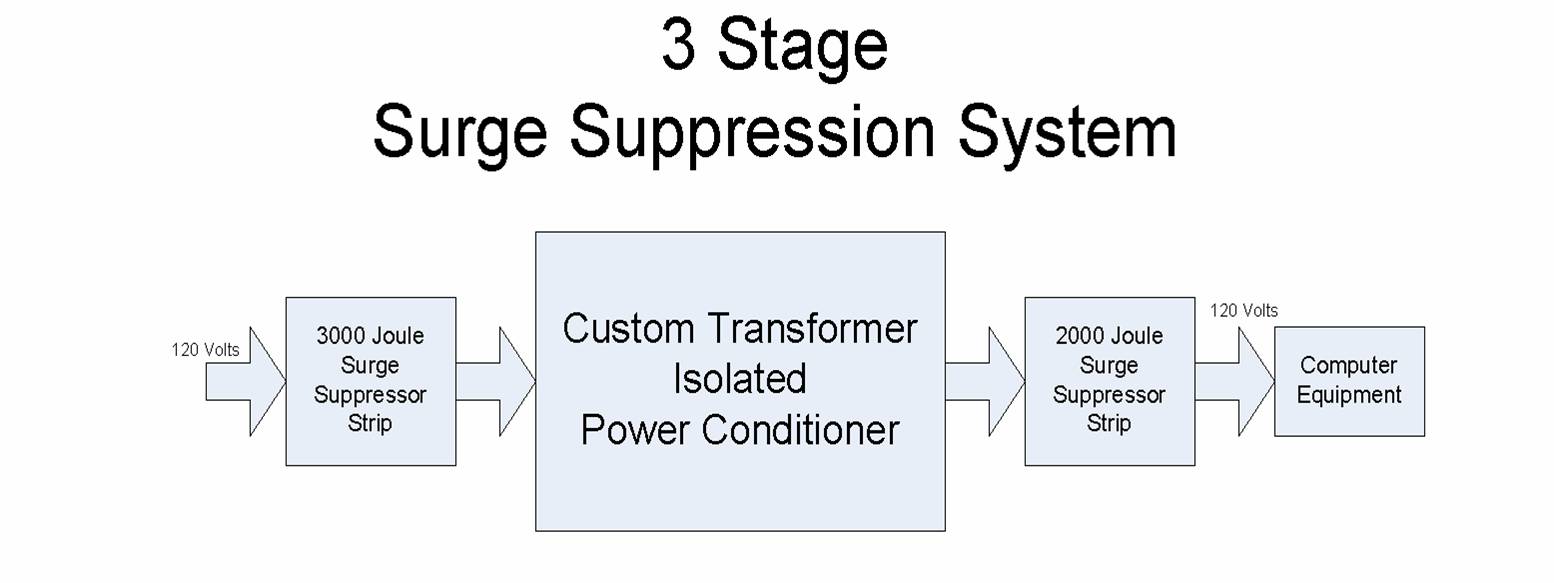

Recent circuit breaker blogs by MIDWEST have dealt with circuit breakers and surge suppressors. For expensive computer equipment, superb surge suppression is vital. Surge suppression is exceedingly cheap insurance for such applications. The initial / replacement equipment costs can be expensive. But even more importantly, downtime and data loss can be catastrophic.

In fact, when putting together my own home computer system, I considered surge suppression so extremely important, that I put together my own 3 stage surge suppression system.

The 3 stage system consists of:

- a 3000 Joule commercial surge suppressor strip, with integral circuit breaker.

- a custom designed and built, transformers isolated power conditioner.

- a 2000 Joule commercial surge suppressor strip.

The 3000 and 2000 Joule commercial surge suppressor strips were the highest quality (i.e. expensive) that I could find. But surge protection is so important, that I considered these insufficient.

Therefore, I additionally designed and built a custom transformer isolated power conditioner. It contains a 2 KVA dry transformer and six metal oxide varistors. It also contains four RC snubber networks for high frequency EMI attenuation. The main purpose of the transformer is to provide additional series impedance. The design of the power conditioner is covered in a separate blog.

The theory behind the entire scheme is that each stage of the surge suppression system helps dissipate the spike’s energy. An applied voltage spike first is partially dissipated by the building’s line impedance and the first 3000 Joule suppressor strip. The portion of the spike that gets through is next attenuated by the custom transformer isolated power conditioner. In addition, this helps slow down steep wavefronts and reduce EMI. The final 2000 Joule surge suppressor strip attenuates whatever spike remains.

A block diagram of the system is shown in the Visio diagram below.

3 Stage Surge Suppression System